(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 24/11/2024 to 7:00 (SGT) 25/11/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

(NW/KF Standard) Plumbing Components, Flanges(Flange Size (Nominal):NW(KF)40 Page2)

| Days to Ship |

|

|---|

-

Both Sides Welded Vacuum Pipes/NW Flanged x Tees

MISUMI

It's a vacuum tube.

[Size added] No.50 is now available.Days to Ship: 8 Day(s) or more -

Both Sides Welded Vacuum Pipes/NW Flanged x Threaded

MISUMI

It's a vacuum tube.

[Size added] No.50 is now available.Days to Ship: 8 Day(s) or more -

Both Sides Welded Vacuum Pipes/NW Flanged x Flanged

MISUMI

It's a vacuum tube.

[Size added] No.50 is now available.Standard Price: SGD 320.08 Days to Ship: 4 Day(s) or more -

MISUMI

[Features]·This product can be easily connected to reducing. [Material]·SUS304.

Standard Price: SGD 232.48 Days to Ship: 4 Day(s) or more -

MISUMI

A new gauge port that connects to a vacuum gauge is now available.

[Size added] No.50 is now available.Standard Price: SGD 353.77- Days to Ship: 4 Day(s) or more -

Standard Price: SGD 303.23 Days to Ship: 4 Day(s) or more -

Fittings for Vacuum Plumbing/NW Flanged x Swaged Sleeve Fitting

MISUMI

This is a joint for gas introduction by welding SUS pipe.

[Size added] No.50 is now available.Standard Price: SGD 126.35- Days to Ship: 4 Day(s) or more -

Fittings for Vacuum Plumbing/NW Flanged x Stainless Steel Pipe/Single Nozzle

MISUMI

Type with SUS pipe welded to NW flange. [Additional size] No. 50 is now available.

Days to Ship: 8 Day(s) or more -

Fittings for Vacuum Plumbing/NW Flanged x Stainless Steel Pipe/Double Nozzle

MISUMI

This product has a SUS pipe welded to the NW flange.

[Size added] No.50 is now available.Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - Tees](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774089/110310774089_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - Tees

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.[Features]·A Fitting Tee for Vacuum Plumbing. [Material]·SUS304.

Standard Price: SGD 153.30- Days to Ship: 8 Day(s) or more -

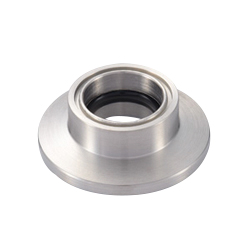

![[Clean & Pack]Fittings for Vacuum Plumbing - Reducer](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774179/110310774179_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - Reducer

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.[Features]·A Fitting Reducer for Vacuum Plumbing. [Material]·SUS304.

Standard Price: SGD 76.60- Days to Ship: 8 Day(s) or more -

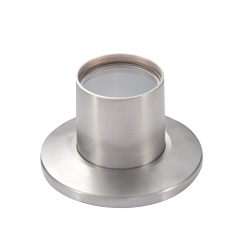

![[Clean & Pack]Fittings for Vacuum Plumbing - Male Adapter](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774269/110310774269_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - Male Adapter

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.[Features]·A Fitting Male Adapter for Vacuum Plumbing. [Material]·SUS304.

Standard Price: SGD 70.10- Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - Both Ends NW Flanged](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774359/110310774359_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Both Sides Weld-On Vacuum Pipes - Both Ends NW Flanged

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.A SUS304 Both Sides Weld-On Vacuum Pipes.

Days to Ship: 12 Day(s) or more -

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Elbow](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774449/110310774449_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Elbow

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 12 Day(s) or more -

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Tees](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774539/110310774539_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Tees

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Days to Ship: 12 Day(s) or more -

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VF Flanged](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774629/110310774629_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VF Flanged

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Standard Price: SGD 315.40- Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VG Flanged](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774719/110310774719_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VG Flanged

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.Standard Price: SGD 315.40- Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - Reducing Tees](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774809/110310774809_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - Reducing Tees

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.[Features]·It also makes it easier to connect different diameters. [Material]·SUS304.

Standard Price: SGD 210.90- Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Blind Flanged](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310777419/110310777419_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - NW Blind Flanged

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

[Features]·An NW Blind Flanged Fitting for Vacuum Plumbing. [Material]·SUS304.Standard Price: SGD 23.00- Days to Ship: 8 Day(s) or more -

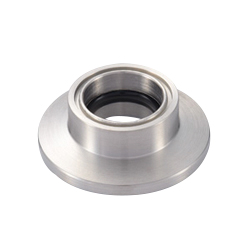

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310777509/110310777509_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

[Features]·Fittings for Vacuum Plumbing.Standard Price: SGD 26.60- Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Single Nozzle](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310777689/110310777689_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Single Nozzle

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

SUS pipe welded to NW flange

[Additional Size]No. 50 is now selectable.Days to Ship: 12 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Double Nozzle](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844109/110310844109_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Double Nozzle

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

This is a product is a SUS pipe welded to NW flange.

[Additional Size]No. 50 is now selectable.Days to Ship: 12 Day(s) or more -

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Threaded](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844469/110310844469_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Threaded

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

[Additional Size]No. 50 is now selectable.Days to Ship: 12 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - Nipples with Gauge Ports](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844559/110310844559_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - Nipples with Gauge Ports

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

A new gauge port to connect with a vacuum gauge is available.

[Additional Size]No. 50 is now selectable.- Volume Discount

Standard Price: SGD 330.91- Days to Ship: 8 Day(s) or more -

![[Clean & Pack]Fittings for Vacuum Plumbing - Hose Adapter](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844649/110310844649_001_20230911105917.jpg?$product_view_b$)

[Clean & Pack]Fittings for Vacuum Plumbing - Hose Adapter

MISUMI

Three types of cleaning methods are available: degreasing, precision cleaning, and electrolytic polishing + precision cleaning. They can be ordered from one piece with the standard part number.

This eliminates the need for customer cleaning or outsourced cleaning, reducing the amount of time and effort required.■Part Number for Clean & Pack Products· Degreasing (Anti-rust single packing) : Part Number SL-□□ · Precision cleaning (Degassing double packing) : Part Number SH-□□ · Electrolytic polishing + precision cleaning (Degassing double packing) : Part Number SHD-□□ Product Part Number Cleaning Method Packaging Type Effects Compared to Uncleaned Product Environment (Standard) Process SL-□□ Degreasing Anti-Rust Packing Oil Removal General Environment Regular Assembly Process Post Battery Assembly Process SH-□□ Precision Cleaning Degassing Double Packing Oil Removal

Dust RemovalClean Environment (Class 10 to 1,000) Battery Assembly Process LCD-Related Post Assembly Process In-Vehicle Camera Assembly Process SHD-□□ Electrolytic Polishing + Precision Cleaning Degassing Double Packing Oil Removal

Dust Removal

Outgas ReductionVacuum Environment

Clean Environment (Class 10 to 1,000)Pre-Semiconductor Process Liquid Crystal Deposition Process Pre-OLED Process ■ Notes

Cleaning also removes rust prevention oil, which may make the product more susceptible to rusting than an uncleaned product.

Please be careful about the application location and storage environment.

[Features]·Can be connected to a hose. [Material]·SUS304.- Volume Discount

Standard Price: SGD 283.70- Days to Ship: 8 Day(s) or more -

MIRAPRO

NW flange elbow conversion fitting for vacuum piping.

[Features]

·A wide variety of variations are available from NW10 to NW100.

·NW elbow for vacuum piping.

[Applications]

·A joint for easily and inexpensively bending a vacuum piping line with an NW flange shape to 90 degrees.Standard Price: SGD 106.51 Days to Ship: 4 Day(s) or more -

MIRAPRO

The connection pipe uses JIS standard sizes (outer diameter 20mm, thickness 2mm pipe on KF16 only). The sealing surface of the flange is protected by a cap and tape.

Standard Price: SGD 96.37 Days to Ship: 4 Day(s) or more -

Standard Price: SGD 126.58 Days to Ship: 4 Day(s) or more -

ADVANTEC(VACUUM PIPING)

[Features]

· Products conforming to special dimensions can be fabricatedStandard Price: SGD 159.82 Days to Ship: 4 Day(s) or more -

NW Connection Part Special NW Cross

ADVANTEC(VACUUM PIPING)

High quality. Quick delivery. Low cost.

[Features]

· Products with special dimensions can be manufactured.

・In the case of SUS316L, direct use of "-6L" at end of the model number (OR316L).

· Surface treatment: G.B.BStandard Price: SGD 644.83 Days to Ship: 4 Day(s) or more -

Adapter Series, NW Gauge Port with Flange

ADVANTEC(VACUUM PIPING)

High-quality, fast delivery, and low-cost.

Standard Price: SGD 168.97 Days to Ship: 19 Day(s) or more -

Adapter Series, NW Flange + VCR Adapter

ADVANTEC(VACUUM PIPING)

High quality. Quick delivery. Low cost.

Standard Price: SGD 122.97- Days to Ship: 4 Day(s) or more -

EVAC Glass Blank Flange NW 16-63

EVAC

We offer an extensive lineup of safe and reliable Evac brand products. For Evac products—visit MiSUMi.

[Features]

Glass blanking flange. We offer a lineup of Duran®

(borosilicate glass) and two types of quartz materials.

· Besides using for corrosion-resistant applications where metals cannot be used, these flanges can also be used as a viewing port due to their transparency for easy internal visual monitoring.

・ Enhanced internal visual monitoring—ideal for controlling plasma and high temperature processes.

· Duran®: Cuts out ultraviolet light.

· Quartz: Optimally suited for transmitting ultraviolet light.

· Supports vacuum pressures down to 10–7 Pa.

· Supports pressurization up to 0.2 MPa.

· Maximum operating temperatures: Duran® 450℃/Quartz 1000℃.

· We also offer a lineup of optically polished viewports for transmitting laser light.Standard Price: SGD 219.69 Days to Ship: 4 Day(s) or more -

COSMOTEC

Variety of reliable Cosmotec products are available.

[Features]

· Standard parts of various sizes of short and long flanges for welding in addition to blank flanges for sealing and machining are available.

· Are also able to provide in SUS316L.Standard Price: SGD 21.36 Days to Ship: 4 Day(s) or more -

COSMOTEC

A wide array of Cosmotec products is available. Realizing reassuring and reliable manufacturing.

[Features]

· Used to adjust the length of pipes, etc.

· NW/KF to NW/KF50 were standardized to a length of 100 mm.

· Offers standard conversion nipples as standard.

· We respond quickly to custom orders including changes to L dimensions, etc.Standard Price: SGD 100.36 Days to Ship: 10 Day(s) or more -

NW/KF Standard Conversion Nipple

COSMOTEC

NW/KF standard compatible conversion nipple. [Applications]·For vacuum vessel piping systems, etc.

Standard Price: SGD 81.49 Days to Ship: 4 Day(s) or more -

COSMOTEC

Variety of reliable Cosmotec products are available.

[Features]

· Used to change the angle of pipes, for example.

· NW/KF16-NW/KF50 are standardized.

· We respond quickly to a request for customization such as change in dimensions.Standard Price: SGD 127.61 Days to Ship: 25 Day(s) or more -

COSMOTEC

It is used for mounting boats for vacuum gauges, exhaust connection ports, etc.

[Features]

・ NW / KF16 to NW / KF50 are standardized

[Applications]

・ Vacuum vessel piping systemStandard Price: SGD 272.72- Days to Ship: 4 Day(s) or more -

COSMOTEC

Variety of reliable Cosmotec products are available.

[Features]

· For ports of vacuum gauges (mounting ports, exhaust connection ports, etc.)

· NW/KF16-NW/KF50 are standardized.

· Replacement crosses with two flanges different in size from the other two are also available as standard products.

· The 6-direction cross enables the use of whatever variation comes to mind.

· We respond quickly to a request for customization such as change in dimensions.Standard Price: SGD 1,137.84 Days to Ship: 7 Day(s) or more -

NW/KF Standard Conversion Cross

COSMOTEC

Variety of reliable Cosmotec products are available.

[Features]

· For ports of vacuum gauges (mounting ports, exhaust connection ports, etc.)

· NW/KF16-NW/KF50 are standardized.

· Replacement crosses with two flanges different in size from the other two are also available as standard products.

· The 6-direction cross enables the use of whatever variations come to mind.

· We respond quickly to a request for customization such as change in dimensions.Standard Price: SGD 475.52- Days to Ship: 4 Day(s) or more -

NW/KF Standard, Tapered Female Thread Adapter

COSMOTEC

It is a versatile inch fitting and an adapter that can be converted with a single action.

[Features]

・ 1/4, 3/8, 1/2 inch, NW / KF16 to NW / KF50 are standardized

[Applications]

・ It is used for vacuum vessel piping systemStandard Price: SGD 150.65- Days to Ship: 4 Day(s) or more -

COSMOTEC

Variety of reliable Cosmotec products are available.

[Features]

· Used mainly for vacuum breakage.

· NW/KF16-NW/KF50 are standardized.

· A type with leak valve in the center of the nipple is also available.Standard Price: SGD 328.81 Days to Ship: 10 Day(s) or more -

NW/KF Standard Nipple Leak Port

COSMOTEC

It is mainly used for vacuum breaking.

[Features]

・ NW / KF16 to NW / KF50 are standardized

[Applications]

・ It is used for vacuum vessel piping systemStandard Price: SGD 448.28 Days to Ship: 7 Day(s) or more -

NW/KF Standard Kovar Glass View Port

COSMOTEC

[Features]

・ Kovar glass type for visually observing the inside of the vacuum chamber

・ Various lineups such as single crystal sapphire, fused quartz, synthetic quartz used for optical applications

・ AR coating can be applied to improve the transmission of specific wavelengths

[Applications]

・ It is used for vacuum vessel piping systemStandard Price: SGD 481.81 Days to Ship: 7 Day(s) or more -

NW/KF Standard, Sapphire Glass, Viewport

COSMOTEC

Numerous Cosmotec products are available, helping to create a stable and reliable manufacturing industry.

Standard Price: SGD 1,605.23 Days to Ship: 10 Day(s) or more

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Pipe O.D.(mm) |

| I.D.(mm) |

| Type |

| Flange Shape |

| Flange Type |

| Fitting Type |

| Material |

| Flange Size (Nominal) |

| Flange Size Small Dia. or Conversion Destination Dia. |

| Adaptor Type |

| Standard |

| Equal Dia. / Unequal Dia. |

| Cleaning Method |

| Characteristics/Applications |

| Environmentally friendly |

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MIRAPRO | MIRAPRO | MIRAPRO | ADVANTEC(VACUUM PIPING) | ADVANTEC(VACUUM PIPING) | ADVANTEC(VACUUM PIPING) | ADVANTEC(VACUUM PIPING) | EVAC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC | COSMOTEC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product Series | Fittings for Vacuum Plumbing/NW Flanged x Swaged Sleeve Fitting | Fittings for Vacuum Plumbing/NW Flanged x Stainless Steel Pipe/Single Nozzle | Fittings for Vacuum Plumbing/NW Flanged x Stainless Steel Pipe/Double Nozzle | [Clean & Pack]Both Sides Weld-On Vacuum Pipes - Both Ends NW Flanged | [Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Elbow | [Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Tees | [Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VF Flanged | [Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VG Flanged | [Clean & Pack]Fittings for Vacuum Plumbing - NW Blind Flanged | [Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Single Nozzle | [Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Double Nozzle | [Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Threaded | [Clean & Pack]Fittings for Vacuum Plumbing - Nipples with Gauge Ports | ||||||||||||||||||||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||||||||||

| Days to Ship | 8 Day(s) or more | 8 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 12 Day(s) or more | 12 Day(s) or more | 12 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 12 Day(s) or more | 12 Day(s) or more | 12 Day(s) or more | 8 Day(s) or more | 8 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 19 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 10 Day(s) or more | 4 Day(s) or more | 25 Day(s) or more | 4 Day(s) or more | 7 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 10 Day(s) or more | 7 Day(s) or more | 7 Day(s) or more | 10 Day(s) or more |

| Pipe O.D.(mm) | 42.7 | 17.3 | 42.7 | - | 25 ~ 28 | - | 9.53 ~ 10 | - | - | 42.7 | 21.7 ~ 27.2 | 13.8 ~ 27.2 | 42.7 | 42.7 | 42.7 | 42.7 | 42.7 | - | 55 | 42.7 | - | - | 17.3 | 25 ~ 28 | - | 42.7 | 42.7 | - | 42.7 | 42.7 | - | - | - | - | 42.7 | - | 42.7 | 38.1 | 38.1 | 38.1 | - | - | - | - | - |

| I.D.(mm) | 37.1 | 12.7 | 37.1 | - | 16 ~ 19 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 37.1 | 37.1 | 16 | - | - | - | 37.1 | - | 37.1 | 34.8 | 34.8 | 34.8 | - | - | - | - | - |

| Type | Fitting | Adapter | Adapter | Fitting | Adapter | Adapter | Fitting | Fitting | Fitting | Fitting | Fitting | Adapter | Fitting | Fitting | Fitting | Adapter | Adapter | Fitting | Flange | Flange | Fitting | Fitting | Adapter | Fitting | Adapter | Fitting | Fitting | Adapter | Fitting | Fitting | Adapter | Adapter | Flange | Flange | Fitting | Fitting | Fitting | Fitting | Fitting | Fitting | Adapter | Adapter | Adapter | Flange | Flange |

| Flange Shape | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Blank | Standard | Flanges with Introduction Pipe | Flanges with Introduction Pipe | - | - | - | - | - | - | - | - | - | - | Blank | Blank | - | - | - | - | - | - | - | - | - | Viewport | Viewport |

| Flange Type | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | Others | Short | Others | Others | - | - | - | - | - | - | - | - | - | - | - | Others | - | - | - | - | - | - | - | - | - | Others | Others |

| Fitting Type | Tees | - | - | Tees | - | - | Others | Others | Others | Tees | Reducers | Reducers | Nipples | Elbows | Tees | Reducers | Reducers | Tees | - | - | Others | Others | Reducers | Tees | Reducers | Elbows | Elbows | - | Tees | Cross | - | - | - | - | Nipples | Nipples | Elbows | Tees | Cross | Cross | - | - | - | - | - |

| Material | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS316L | Borosilicate Glass | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 | SUS304 |

| Flange Size (Nominal) | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 | NW(KF)40 |

| Flange Size Small Dia. or Conversion Destination Dia. | - | - | - | NW(KF)25 | - | - | - | - | - | - | NW(KF)16 ~ NW(KF)25 | - | - | - | - | - | - | NW(KF)25 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | NW(KF)16 ~ NW(KF)25 | - | NW(KF)16 ~ NW(KF)25 | NW(KF)40 | NW(KF)16 ~ NW(KF)25 | - | - | - | - | - |

| Adaptor Type | - | Others | JIS Flanged | - | Gage Ports | Others | - | - | - | - | For Standard Conversion | Screws | - | - | - | For Standard Conversion | For Standard Conversion | For Standard Conversion | - | - | - | - | Screws | Gage Ports | For Rubber Pipe and Tube Installation | - | - | Leak Port | - | - | Gage Ports | VCR Female ~ VCR Male | - | - | - | - | - | - | - | - | Screws | Leak Port | Leak Port | - | - |

| Standard | - | - | - | - | - | - | - | - | - | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | NW/KF Standard | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Equal Dia. / Unequal Dia. | - | - | - | - | - | - | - | - | - | Equal Dia. | Unequal Dia. | Unequal Dia. | Equal Dia. | Equal Dia. | Equal Dia. | Unequal Dia. | Unequal Dia. | Unequal Dia. | Equal Dia. | Equal Dia. | Equal Dia. | Equal Dia. | Unequal Dia. | Equal Dia. | Unequal Dia. | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Cleaning Method | - | - | - | - | - | - | - | - | - | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | Degreasing / Precision Cleaning / Electrolytic Polishing + Precision Cleaning | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Characteristics/Applications | - | - | - | - | - | - | - | - | - | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | Clean washed | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Environmentally friendly | - | - | - | - | - | - | - | - | - | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | RoHS Compliant (10 Substances) | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Pipe O.D.(mm)

-

I.D.(mm)

-

Type

- Flange

- Fitting

- Adapter

-

Flange Shape

-

Flange Type

- Short

- Long

- Others

-

Fitting Type

- Nipples

- Elbows

- Reducers

- Tees

- Cross

- Others

-

Material

-

Flange Size (Nominal)

-

Flange Size Small Dia. or Conversion Destination Dia.

-

Adaptor Type

-

Standard

- NW/KF Standard

-

Equal Dia. / Unequal Dia.

- Equal Dia.

- Unequal Dia.

-

Cleaning Method

- Degreasing

- Precision Cleaning

- Electrolytic Polishing + Precision Cleaning

-

Characteristics/Applications

- Clean washed

-

Environmentally friendly

- RoHS Compliant (10 Substances)

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

![[Clean & Pack]Fittings for Vacuum Plumbing - Tees](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774089/110310774089_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Reducer](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774179/110310774179_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Male Adapter](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774269/110310774269_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - Both Ends NW Flanged](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774359/110310774359_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Elbow](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774449/110310774449_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Tees](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774539/110310774539_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VF Flanged](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774629/110310774629_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VG Flanged](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774719/110310774719_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Reducing Tees](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310774809/110310774809_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Blind Flanged](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310777419/110310777419_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310777509/110310777509_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Single Nozzle](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310777689/110310777689_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Double Nozzle](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844109/110310844109_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Threaded](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844469/110310844469_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Nipples with Gauge Ports](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844559/110310844559_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Hose Adapter](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/jp/product/series/110310844649/110310844649_001_20230911105917.jpg?$product_view_b$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Tees](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774089/110310774089_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Reducer](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774179/110310774179_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Male Adapter](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774269/110310774269_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - Both Ends NW Flanged](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774359/110310774359_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Elbow](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774449/110310774449_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Tees](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774539/110310774539_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VF Flanged](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774629/110310774629_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × VG Flanged](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774719/110310774719_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Reducing Tees](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310774809/110310774809_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Blind Flanged](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310777419/110310777419_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310777509/110310777509_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Single Nozzle](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310777689/110310777689_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - NW Flanged × Stainless Steel Pipe, Double Nozzle](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310844109/110310844109_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Both Sides Weld-On Vacuum Pipes - NW Flanged × Threaded](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310844469/110310844469_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Nipples with Gauge Ports](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310844559/110310844559_001_20230911105917.jpg?$product_view_c$)

![[Clean & Pack]Fittings for Vacuum Plumbing - Hose Adapter](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/jp/product/series/110310844649/110310844649_001_20230911105917.jpg?$product_view_c$)

How can we improve?

How can we improve?