(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 24/11/2024 to 7:00 (SGT) 25/11/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Single Axis Actuators

| Days to Ship |

|

|---|

-

- Recommendation

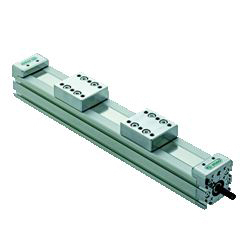

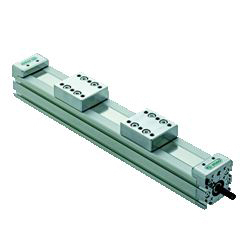

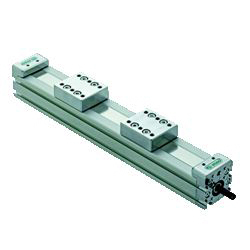

Single Axis Actuators KS86 Standard/KSC86 With Cover

MISUMI

This is an economy item, The price is cheaper than the MISUMI standard product.

- Volume Discount

Days to Ship: 5 Day(s) or more -

- Recommendation

Single Axis Actuators KS60 Standard/KSC60 With Cover

MISUMI

This is an economy item, The price is cheaper than the MISUMI standard product.

- Volume Discount

Days to Ship: 5 Day(s) or more -

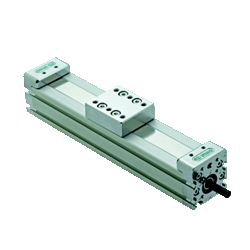

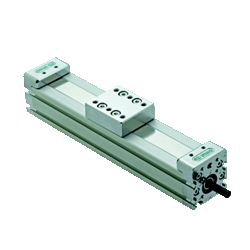

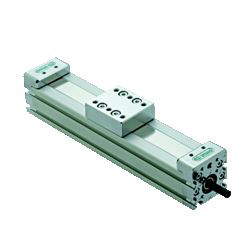

Single Axis Actuators LX30 Standard / Cover Type

MISUMI

MISUMI Single Axis Actuators LX30 Standard/Cover Type are high-precision linear motion devices tailored for diverse industrial and automation applications, known for their robustness and flexibility.

Key Features:

Motor Mounting Orientation: Straight, for flexible installation.

Main Body and Components: The main body provided, with customer-installed motors.

Ball Screw Shaft: 10 mm diameter with a rolled ball screw drive for smooth, accurate movement.

Slider Material: Chrome molybdenum steel for strength and durability.

Durable Construction: Designed to withstand rigorous industrial environments.

High Precision: Ensures accurate positioning for critical applications.

Customizable Setup: Adaptable to a variety of industrial setups and requirements.Ideal for tasks requiring precise, controlled linear movement, these actuators are a robust choice for industrial machinery and automation systems.Days to Ship: 5 Day(s) or more -

Single Axis Actuators KS50 Standard/KSC50 With Cover

MISUMI

This is an economy item, The price is cheaper than the MISUMI standard product.

- Volume Discount

Days to Ship: 5 Day(s) or more -

Single Axis Actuators KS40 Standard/KSC40 With Cover

MISUMI

This is an economy item, The price is cheaper than the MISUMI standard product.

- Volume Discount

Days to Ship: 5 Day(s) or more -

Single Axis Actuators LX20 Standard / Cover Type

MISUMI

The MISUMI Single Axis Actuators LX20 Standard/Cover Type are precision linear motion devices designed for various industrial and automation applications, notable for their robust construction and customizable options.

Key Features:

Motor Mounting Orientation: Straight orientation.

Main Body and Components: Main body as the primary component; motors installed by customers.

Table Length: 33.2 mm, compact yet effective working area.

Ball Screw Shaft: Diameter of 6 mm with rolled ball screw drive method.

Slider Material: Chrome molybdenum steel for strength and durability.

Surface Treatment: Low-temperature black chrome treatment for resilience.

Operating Temperature: Effective operation in temperatures from 0°C to 50°C.

These actuators are ideal for applications requiring precise, controlled linear movement, and their durable construction makes them suitable for both industrial machinery and automation systems.Days to Ship: 5 Day(s) or more -

Single Axis Actuators LX26 Standard / Cover Type

MISUMI

MISUMI's Single Axis Actuators LX26 Standard/Cover Type are high-precision linear motion devices suitable for a wide range of industrial and automation applications. These actuators are designed for flexibility and efficiency.

Key Features:

Motor Mounting Orientation: Straight, allowing for versatile installation options.

Main Body and Components: Main body provided, with motors to be installed by the customer.

Table Length: 47.4 mm, offering a compact and efficient working area.

Ball Screw Shaft: Diameter of 8 mm with a rolled ball screw drive method for precise movement.

Slider Material: Constructed from chrome molybdenum steel, ensuring strength and longevity.

Surface Treatment: Slider treated with low-temperature black chrome for enhanced durability.

Operating Temperature: Capable of operating in ambient temperatures ranging from 0°C to 50°C.

Designed for both robustness and precision, these actuators are ideal for applications that require reliable and controlled linear movement, enhancing productivity and operational efficiency.Days to Ship: 5 Day(s) or more -

Single Axis Actuators LX45 Standard / Cover Type

MISUMI

The MISUMI Single Axis Actuators LX45 Standard/Cover Type are designed for high-precision linear motion in a variety of industrial and automation applications. These actuators are recognized for their robust construction and high functionality.

Key Features:

Motor Mounting Orientation: Straight, allowing for versatile installation options.

Main Body and Components: The main body is the primary component, with motors to be installed by the customer.

Drive Method: Features a rolled ball screw for smooth and precise motion.

Slider Material: Made from chrome molybdenum steel, ensuring strength and durability in demanding applications.

Additional Specifications: Detailed specifications include a standard length of 1 pc, a cover provided, and various other dimensions and features.

Ideal for tasks requiring precise, controlled linear movement, these actuators are a robust choice for industrial machinery and automation systems.Days to Ship: 5 Day(s) or more -

Single Axis Actuators LX30 Motor Folded Type

MISUMI

The MISUMI Single Axis Actuators LX30 Motor Folded Type are designed for high-precision linear motion, suitable for various industrial and automation applications. These actuators are known for their compact design and adaptability.

Key Features:

Actuator Type: Linear axis actuator with cover, offering protection and enhanced durability.

Motor Mounting: Folded type motor mounting for space efficiency.

Dimensions: Short actuator length for compact applications.

Pulley Diameter Options: Available with no attachment, pulley inner diameter options of Ø6 and Ø8.

Size and Capacity: Designed to accommodate specific size and weight requirements, ensuring suitability for various applications.

Ideal for tasks requiring precise and controlled linear movement, these actuators are a robust choice for industrial machinery and automation systems.Days to Ship: 10 Day(s) -

THK

With a compact and highly stiff structure that integrates the LM guide, ball screw, and support unit, 5 semi-custom made actuators ideal for high accurate positioning are available.

[Features]

[5 custom made]

・ Dowel Holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products

・ Positioning metal bolt: Positioning metal bolts are installed for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance

・ AFF grease for clean environment: THK and AFF grease are sealed for a clean environment to suppress dust generation

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tabDays to Ship: 24 Day(s) or more -

- On Sale Till 31/12/2024

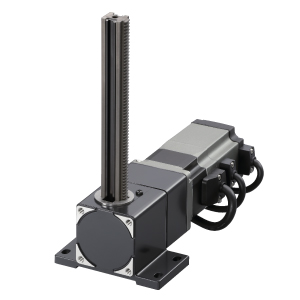

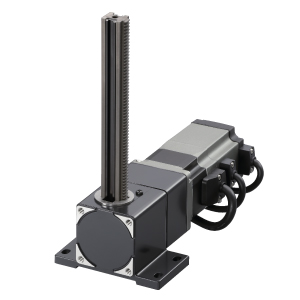

Compact Linear Actuator DRL Series

ORIENTAL MOTOR

This product achieves linear motion using a unified stepping motor and ball screw. By cutting coupling and other mechanism parts this equipment is miniaturized with high accuracy positioning, contributing to improve equipment performance. In addition to the pulse stream input type, the FLEX type with built-in positioning support function, which provides a high level of freedom in system configuration as well as function.

Standard Price: SGD 1,116.00- Special Price Days to Ship: 37 Day(s) -

Standard Price: SGD 1,286.00- Special Price Days to Ship: 17 Day(s) -

THK

A compact, high stiffness, and high precision actuator with an integrated inner block consisting of an LM block and a ball screw nut.

Also, since the housing A/B doubles as a support unit, and the inner block doubles as a table,

it has become possible to significantly reduce design and assembly labor-hours.

[Features]

・ Since it is arranged at a contact angle of 45° so that the load is equal in 4 directions, it can be used in any posture.

・ Since the straight guide section has a 4-row circular arc groove, there is no gap and highly stiff guidance can be obtained.

・ Changes in frictional resistance due to load fluctuations are minimized and follow high precision feed.

・ The U-shaped cross-sectional outer rail improves stiffness against moments and twists.

[Effect of adopting ball retainer]

·Due to the improved grease holding capacity, long-term maintenance-free operation has been achieved. (Lubricator QZ is attached to the ball screw section)

・ Excellent sliding performance can be obtained due to elimination of mutual friction between balls and reduced torque fluctuation.

・ In addition, the basic dynamic load rating of the LM guide and ball thread section is larger than before, so it has a long lifespan.Days to Ship: 24 Day(s) or more -

Standard Price: SGD 1,286.00- Special Price Days to Ship: 17 Day(s) -

Single Axis Actuators LX45 Motor Folded Type

MISUMI

■ Features· MISUMI Products: High accuracy, high rigidity, compact LX, low-cost LS, KU that's ideal for high accuracy and high load capacity. You can select LX with motor (servo motor, stepper motor) or without motor. Fast delivery and low price even on a large order.

Days to Ship: 10 Day(s) -

THK

A compact, high-rigidity and high-precision actuator with an integrated inner block consisting of an LM block and ball screw nut.

In addition, as the housing A/B serves as a support unit and the inner block serves as a table, it is possible to dramatically reduce the steps in designing and assembling.

[Features]

· Arranged to make contact at an angle of 45° such that the load is equal in 4 directions, enabling use in various positions.

· The linear guide is made of 4 rows of circular arced grooves for a highly rigid guide with no cracks.

· Changes to friction resistance due to changes in load are suppressed as far as possible, promoting high-accuracy feeding.

· The U-shaped cross-sectional outer rail improves rigidity against moment and torsion.

[Effects of Using Ball Retainer]

· The grease retention capacity has been improved, allowing long-term maintenance-free operation. (QZ Lubricator is attached to the ball screw.)

· Eliminates mutual friction between balls, reduces torque fluctuation and achieves excellent sliding performance.

· In addition, since the basic dynamic load rating of the LM guide and ball screw is higher than conventional products, it has a long service life.Days to Ship: 24 Day(s) or more -

Days to Ship: 5 Day(s) or more -

THK

A compact, high stiffness, and highly accurate actuator with an integrated inner block consisting of an LM block and a ball screw nut.

Also, the housing A/B doubles as a support unit, and the inner block doubles as a table.

It has become possible to significantly reduce design and assembly labor-hours.

[Features]

・ Since it is arranged at a contact angle of 45° so that the load is equal in 4 directions, it can be used in any posture.

・ Since the straight guide section has a 4-row circular arc groove, there is no gap and highly stiff guidance can be obtained.

・ Changes in frictional resistance due to load fluctuations are minimized and follow high accurate feed.

・ The U-shaped cross-sectional outer rail improves stiffness against moments and twists.Days to Ship: 24 Day(s) or more -

- On Sale Till 31/12/2024

Rack and Pinion System, L Series

ORIENTAL MOTOR

The Rack and Pinion System L-Series enables compact, high-power linear transport.

The absolute system with hybrid control system AlphaStep AZ Series allows easy origin setting and origin return.Standard Price: SGD 1,286.00- Special Price Days to Ship: 17 Day(s) -

![Single Axis Actuators LS10 [C-Value - Driven by Ball Screw]](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/cn/product/series/110302633950/110302633950_20201112120924.jpg?$product_view_b$)

Single Axis Actuators LS10 [C-Value - Driven by Ball Screw]

MISUMI

Single Axis Actuators enabling medium accuracy transferring/positioning operations economically.

Days to Ship: 10 Day(s) or more -

THK

A compact, high stiffness, and high precision actuator with an integrated inner block consisting of an LM block and a ball screw nut.

Also, the housing A/B doubles as a support unit, and the inner block doubles as a table.

Therefore, it has become possible to significantly reduce design and assembly labor-hours.

[Features]

・ Since it is arranged at a contact angle of 45° so that the load is equal in 4 directions, it can be used in any posture.

・ Since the straight guide section has a 4-row circular arc groove, there is no gap and highly stiff guidance can be obtained.

・ Changes in frictional resistance due to load fluctuations are minimized and follow high precision feed.

・ The U-shaped cross-sectional outer rail improves stiffness against moments and twists.Days to Ship: 24 Day(s) or more -

![Single Axis Actuators LS12 [C-Value - Driven by Ball Screw]](//sg.misumi-ec.com/linked/material/mech/MSM1/PHOTO/10302634040.jpg?$product_view_b$)

Single Axis Actuators LS12 [C-Value - Driven by Ball Screw]

MISUMI

Single Axis Actuators enabling medium accuracy level transferring/positioning operations economically.

Days to Ship: 11 Day(s) or more -

![Single Axis Actuators LST10 [C-Value - Driven by Belt]](//content.misumi-ec.com/image/upload/t_product_view_b/v1/p/cn/product/series/110302634130/110302634130_20201112120924.jpg?$product_view_b$)

Single Axis Actuators LST10 [C-Value - Driven by Belt]

MISUMI

Belt-driven Single Axis Actuators enabling long stroke- /fast speed-transferring/positioning operations economically.

Days to Ship: 45 Day(s) or more -

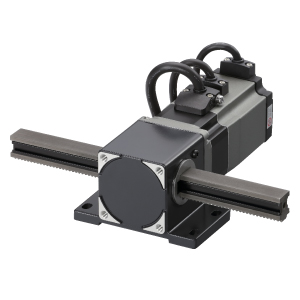

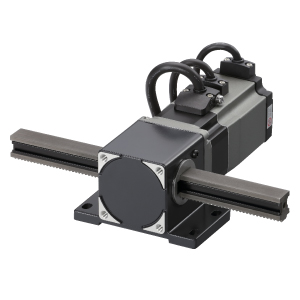

Actuator Unit (Opening and Closing Type) (MAU5040SW)

IMAO CORPORATION

The main body combines stable sliding with T-grooves on three faces for easy mounting, achieving the optimal cross-section shape with maximum strength. The slide mechanism uses materials with excellent abrasion resistance and self-lubrication, and is usable long-term for loads from top, bottom, left, and right.

- CAD :

- 2D

Standard Price: SGD 619.89- Days to Ship: 6 Day(s) or more -

Days to Ship: 5 Day(s) or more -

Motor Adapter Centering Tools for LX30 Actuator

MISUMI

This jig is used to align the axis of the motor attachment.

For LX30 series.Standard Price: SGD 21.61 Days to Ship: 4 Day(s) or more -

Motor Adapter Centering Tools for LX20 Actuator

MISUMI

This is a jig used for aligning the shaft of the motor attachment.For the LX20 series.

Standard Price: SGD 21.61 Days to Ship: 4 Day(s) or more -

- On Sale Till 31/03/2025

![[Medium Accuracy] Motor Bracket Mounting Fixtures for Single Axis Actuators LST10](//sg.misumi-ec.com/linked/material/mech/MSM1/PHOTO/110302634220_001.jpg?$product_view_b$)

[Medium Accuracy] Motor Bracket Mounting Fixtures for Single Axis Actuators LST10

MISUMI

This is a special jig for aligning the axis when attaching the motor bracket to LST10.

Standard Price: SGD 30.32 Special Price Days to Ship: Same day -

IMAO CORPORATION

The main body combines stable sliding with T-grooves on three faces for easy mounting, achieving the optimal cross-section shape with maximum strength. The slide mechanism uses materials with excellent abrasion resistance and self-lubrication, and is usable long-term for loads from top, bottom, left, and right.

- CAD :

- 2D

Standard Price: SGD 385.14- Days to Ship: 9 Day(s) -

THK

With a compact and highly stiff structure that integrates the LM guide, ball screw, and support unit, 5 semi-custom made actuators ideal for high accurate positioning are available.

[Features]

[5 custom made]

・ Dowel Holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products

・ Positioning metal bolt: Positioning metal bolts are installed for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance

・ AFF grease for clean environment: THK and AFF grease are sealed for a clean environment to suppress dust generation

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tabDays to Ship: 24 Day(s) or more -

THK

With a compact and highly stiff structure that integrates the LM guide, ball screw, and support unit, 5 semi-custom made actuators ideal for high accurate positioning are available.

[Features]

[5 custom made]

・ Dowel Holes: Dowel holes are provided for alignment during assembly. It is also useful for preventing misalignment and reproducibility when replacing products

・ Positioning metal bolt: Positioning metal bolts are installed for origin alignment during assembly. It is also useful for reproducibility of the origin position when replacing the motor

・ Sub-table side greasing hole: By processing a grease hole on the side of the sub table and attaching a grease fitting, greasing is possible without removing the cover

・ AP-C processing: Surface treatment (THK, AP-C treatment) is applied to improve corrosion resistance

・ AFF grease for clean environment: THK and AFF grease are sealed for a clean environment to suppress dust generation

[Selection of sensors and sensor rails]

・ Please refer to the selection list on the "Product Information" tabDays to Ship: 24 Day(s) or more -

Motor Adapter Centering Tools for LX26 Actuator

MISUMI

This jig is used to align the axis of the motor attachment.

For LX26 series.Standard Price: SGD 21.61 Days to Ship: 4 Day(s) or more -

Motor Adapter Centering Tools for LX45 Actuator

MISUMI

This jig is used to align the axis of the motor attachment.

For LX45 series.Standard Price: SGD 21.61 Days to Ship: 4 Day(s) or more -

Days to Ship: 5 Day(s) or more -

- On Sale Till 31/12/2024

ORIENTAL MOTOR

Product specifications, product photos, and product catalogs, etc., are currently being finalized.

Standard Price: SGD 200.00 Special Price Days to Ship: 12 Day(s)

| Brand |

|---|

| Product Series |

| CAD |

| Days to Ship |

| Nominal (Height) |

| Accuracy |

| Lead(mm) |

| Table |

| Motor Mounting Orientation |

| Main Body, Peripheral Components |

| Cover |

| With or w/o Motors |

| Table Length L1(mm) |

| Grease |

| Ball Screw Shaft Dia.(Ø) |

| With or w/o Lubricant Unit |

| Table Width W1(mm) |

| Amplifier Voltage |

| With or w/o Retainer |

|

|

|

|

|

|

|

| ||||||||||||||||||||||||||||

| Brand | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | MISUMI | THK | ORIENTAL MOTOR | ORIENTAL MOTOR | THK | ORIENTAL MOTOR | MISUMI | THK | MISUMI | THK | ORIENTAL MOTOR | MISUMI | THK | MISUMI | MISUMI | IMAO CORPORATION | MISUMI | MISUMI | MISUMI | MISUMI | IMAO CORPORATION | THK | THK | MISUMI | MISUMI | MISUMI | ORIENTAL MOTOR |

| Product Series | [Medium Accuracy] Motor Bracket Mounting Fixtures for Single Axis Actuators LST10 | ||||||||||||||||||||||||||||||||||

| CAD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

| Days to Ship | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 5 Day(s) or more | 10 Day(s) | 24 Day(s) or more | 37 Day(s) | 17 Day(s) | 24 Day(s) or more | 17 Day(s) | 10 Day(s) | 24 Day(s) or more | 5 Day(s) or more | 24 Day(s) or more | 17 Day(s) | 10 Day(s) or more | 24 Day(s) or more | 11 Day(s) or more | 45 Day(s) or more | 6 Day(s) or more | 5 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | Same day | 9 Day(s) | 24 Day(s) or more | 24 Day(s) or more | 4 Day(s) or more | 4 Day(s) or more | 5 Day(s) or more | 12 Day(s) |

| Nominal (Height) | 68 / 46 | 48 / 33 | 30 / 40 | 26 / 40 | 32 / 20 | 20 / 27 | 26 / 33 | 45 / 57 | 30 / 40 | 33 | - | - | 26 | - | 45 / 57 | 20 | 15 / 21 | 20 | - | - | 15 | - | - | 58 | - | - | - | - | 58 | 26 | 20 | - | - | - | - |

| Accuracy | Standard Grade | Standard Grade | High Grade / Precision Grade | Standard Grade | Standard Grade | High Grade / Precision Grade | High Grade / Precision Grade | High Grade / Precision Grade | High Grade | Standard Grade | - | - | Standard Grade / High Grade / Precision Grade | - | High Grade | Standard Grade / High Grade / Precision Grade | High Grade / Precision Grade | Standard Grade / High Grade / Precision Grade | - | Standard Grade | High Grade / Precision Grade | Standard Grade | Standard Grade | - | - | - | - | - | - | Standard Grade | Standard Grade | - | - | - | - |

| Lead(mm) | 10 ~ 20 | 5 ~ 10 | 5 ~ 10 | 2 ~ 10 | 1 ~ 6 | 1 ~ 5 | 2 ~ 10 | 10 ~ 20 | 5 ~ 10 | 10 | 1 ~ 8 | - | 2 | - | 10 ~ 20 | 6 | 2 | 1 ~ 6 | - | 2 ~ 4 | 1 ~ 2 | 5 ~ 10 | - | 3 | - | - | - | - | 3 | 2 | 6 | - | - | - | - |

| Table | Long 1 pc. / Long 2 pcs. | Long 1 pc. / Long 2 pcs. | Long 1 pc. / Long 2 pcs. / Short 1 pcs / Short 2 pcs | Long 1 pc. / Long 2 pcs. | Long 1 pc. / Long 2 pcs. | Long 1 pc. / Long 2 pcs. | Long 1 pc. / Long 2 pcs. | Long 1 pc. / Long 2 pcs. / Short 1 pcs / Short 2 pcs | Long 1 pc. / Long 2 pcs. / Short 1 pcs / Short 2 pcs | Long 2 pcs. | - | - | Long 1 pc. | - | Long 1 pc. / Long 2 pcs. / Short 1 pcs / Short 2 pcs | Long 1 pc. / Long 2 pcs. | Long 1 pc. | Long 1 pc. | - | Long 1 pc. | Long 1 pc. | Long 1 pc. | Long 1 pc. | Long 2 pcs. | - | - | - | - | Long 1 pc. | Long 1 pc. | Long 1 pc. | - | - | - | - |

| Motor Mounting Orientation | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Straight | Folded | - | - | - | - | - | Folded | - | Straight | - | - | Straight | - | Straight | Folded | Straight | - | - | - | - | Straight | - | - | - | - | - | - |

| Main Body, Peripheral Components | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | - | Main Body | - | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Main Body | Peripheral Components | Peripheral Components | Peripheral Components | Peripheral Components | Main Body | Main Body | Main Body | Peripheral Components | Peripheral Components | Peripheral Components | - |

| Cover | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | - | - | - | Not Provided / Provided | - | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | - | - | Provided | - | Provided | Provided | Provided | - | - | - | - | Provided | - | - | - | - | - | - |

| With or w/o Motors | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | - | - | Not Provided (Installed by customers) | - | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | - | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | - | - | - | - | Not Provided (Installed by customers) | Not Provided (Installed by customers) | Not Provided (Installed by customers) | - | - | - | - |

| Table Length L1(mm) | 75 | 51 | 28.5 ~ 54 | 47 | 33 | 33.2 | 47.4 | 43.5 ~ 81 | 28.5 ~ 54 | - | - | - | - | - | 43.5 ~ 81 | - | 23 | - | - | 50 | - | 50 | 50 | 55 | - | - | - | - | 55 | - | - | - | - | - | - |

| Grease | Standard | Standard | Standard / Low Particle Generation | Standard | Standard | Standard / Low Particle Generation | Standard / Low Particle Generation | Standard / Low Particle Generation | Standard | Standard | - | - | Standard | - | Standard | Standard | Standard / Low Particle Generation | Standard | - | Standard | Standard | Standard | Standard | Standard | - | - | - | - | Standard | - | - | - | - | - | - |

| Ball Screw Shaft Dia.(Ø) | 15 | 12 | 10 | 8 | 8 | 6 | 8 | 15 | 10 | 13 | - | - | 8 | - | 15 | 6 | 5 | 6 | - | 10 | 5 | 12 | - | - | - | - | - | - | - | 8 | 6 | - | - | - | - |

| With or w/o Lubricant Unit | Not Provided | Not Provided | Not Provided / Provided | Not Provided | Not Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided / Provided | Not Provided | - | - | Not Provided | - | Not Provided / Provided | Not Provided | Not Provided / Provided | Not Provided | - | Not Provided | Not Provided | Not Provided | Not Provided | - | - | - | - | - | - | Not Provided | Not Provided | - | - | - | - |

| Table Width W1(mm) | 60 ~ 112 | 42 ~ 86 | 44.5 ~ 80 | 35 ~ 62 | 26 ~ 52 | 29.6 ~ 52 | 37.6 ~ 62 | 59.5 ~ 104 | 44.5 ~ 80 | - | - | - | - | - | 59.5 ~ 104 | - | 22 ~ 44 | - | - | 62 | - | 80 | 62 | 49 | - | - | - | - | 49 | - | - | - | - | - | - |

| Amplifier Voltage | - | - | - | - | - | - | - | - | - | Not Provided | - | - | Not Provided | - | - | Not Provided | - | Not Provided | - | Not Provided | Not Provided | Not Provided | Not Provided | Not Provided | - | - | - | - | Not Provided | Not Provided | Not Provided | - | - | - | - |

| With or w/o Retainer | - | - | - | - | - | - | - | - | - | Provided | - | - | Provided | - | - | Provided | - | Provided | - | Not Provided | Provided | Not Provided | Not Provided | Not Provided | - | - | - | - | Not Provided | Provided | Not Provided | - | - | - | - |

Loading...

Configure

Specification/Dimensions

-

Nominal (Height)

-

Accuracy

See the accuracy standard of each manufacturer.

-

Lead(mm)

-

Table

-

Motor Mounting Orientation

-

Main Body, Peripheral Components

-

Cover

-

With or w/o Motors

-

Table Length L1(mm)

-

Grease

- Standard

- Low Particle Generation

-

Ball Screw Shaft Dia.(Ø)

-

With or w/o Lubricant Unit

-

Table Width W1(mm)

-

Amplifier Voltage

-

With or w/o Retainer

Narrow search by specifying Manufacturer

CAD

-

- 2D

- 3D

![Single Axis Actuators LS10 [C-Value - Driven by Ball Screw]](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/cn/product/series/110302633950/110302633950_20201112120924.jpg?$product_view_b$)

![Single Axis Actuators LS12 [C-Value - Driven by Ball Screw]](http://sg.misumi-ec.com/linked/material/mech/MSM1/PHOTO/10302634040.jpg?$product_view_b$)

![Single Axis Actuators LST10 [C-Value - Driven by Belt]](http://content.misumi-ec.com/image/upload/t_product_view_b/v1/p/cn/product/series/110302634130/110302634130_20201112120924.jpg?$product_view_b$)

![[Medium Accuracy] Motor Bracket Mounting Fixtures for Single Axis Actuators LST10](http://sg.misumi-ec.com/linked/material/mech/MSM1/PHOTO/110302634220_001.jpg?$product_view_b$)

![Single Axis Actuators LS10 [C-Value - Driven by Ball Screw]](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/cn/product/series/110302633950/110302633950_20201112120924.jpg?$product_view_c$)

![Single Axis Actuators LS12 [C-Value - Driven by Ball Screw]](http://sg.misumi-ec.com/linked/material/mech/MSM1/PHOTO/10302634040.jpg?$product_view_c$)

![Single Axis Actuators LST10 [C-Value - Driven by Belt]](http://content.misumi-ec.com/image/upload/t_product_view_c/v1/p/cn/product/series/110302634130/110302634130_20201112120924.jpg?$product_view_c$)

![[Medium Accuracy] Motor Bracket Mounting Fixtures for Single Axis Actuators LST10](http://sg.misumi-ec.com/linked/material/mech/MSM1/PHOTO/110302634220_001.jpg?$product_view_c$)

How can we improve?

How can we improve?