(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla Firefox.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 24/11/2024 to 7:00 (SGT) 25/11/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

Cam Follower CF-AB Model (CF18VUU-AB)

Compact and rigid shaft bearing with a needle bearing in the cam follower. Ideal for use as a linear motion guide roller in the cam mechanism of automatic and dedicated machines.

[Features]

・ CF-AB model comes with hex sockets at both ends of the stud and grease fitting for lubrication in the back. Can be installed and refilled from both directions.

(i)Caution

- Some of the items are scheduled to be discontinued as of end of March in 2023. The manufacturer keep the items produced but they are not available with Misumi.

There are not the replacement items and the plan to resumption of sale. Please check the quotation and order screen for details.

Japanese Only

Part Number

Configured Part Number is shown.

CF18VUU-AB

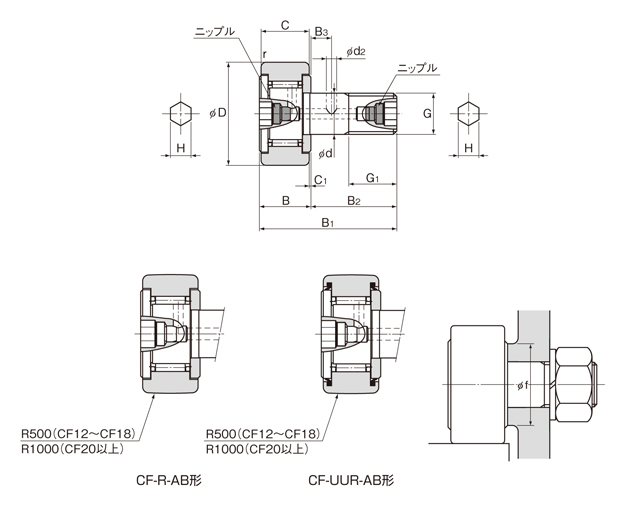

Drawing

Product Specifications

| Optional specifications | Symbol | |

|---|---|---|

| Guidance method of the roller | With cage | No symbol |

| Full rollers | V | |

| Materials | Carbon steel | No symbol |

| Stainless steel | M | |

| Seal | No Seal | No symbol |

| With seal | UU | |

| Outer ring shape | Cylindrical Outer Ring | No symbol |

| Spherical Outer Ring | R | |

Standards Table

| Stud diameter d | Part number | Main dimensions | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Outer Diameter D | Outer ring width C | Thread G | G1 | B | Overall length B1 | B2 | B3 | C1 | d2 | H | r smin | Shoulder dimensions f (Minimum) | ||

| 12 | CF 12-AB | 30 | 14 | M12 × 1.5 | 13 | 15 | 40 | 25 | 6 | 0.6 | 3 | 6 | 0.6 | 20 |

| 12 | CF 12-1-AB | 32 | 14 | M12 × 1.5 | 13 | 15 | 40 | 25 | 6 | 0.6 | 3 | 6 | 0.6 | 20 |

| 16 | CF 16-AB | 35 | 18 | M16 × 1.5 | 17 | 19.5 | 52 | 32.5 | 8 | 0.8 | 3 | 6 | 0.6 | 24 |

| 18 | CF 18-AB | 40 | 20 | M18 × 1.5 | 19 | 21.5 | 58 | 36.5 | 8 | 0.8 | 3 | 6 | 1 | 26 |

| 20 | CF 20-AB | 52 | 24 | M20 × 1.5 | 21 | 25.5 | 66 | 40.5 | 9 | 0.8 | 4 | 8 | 1 | 36 |

| 20 | CF 20-1-AB | 47 | 24 | M20 × 1.5 | 21 | 25.5 | 66 | 40.5 | 9 | 0.8 | 4 | 8 | 1 | 36 |

| 24 | CF 24-AB | 62 | 29 | M24 × 1.5 | 25 | 30.5 | 80 | 49.5 | 11 | 0.8 | 4 | 8 | 1 | 40 |

| 24 | CF 24-1-AB | 72 | 29 | M24 × 1.5 | 25 | 30.5 | 80 | 49.5 | 11 | 0.8 | 4 | 8 | 1 | 40 |

| 30 | CF 30-AB | 80 | 35 | M30 × 1.5 | 32 | 37 | 100 | 63 | 15 | 1 | 4 | 8 | 1 | 46 |

| 30 | CF 30-1-AB | 85 | 35 | M30 × 1.5 | 32 | 37 | 100 | 63 | 15 | 1 | 4 | 8 | 1 | 46 |

| 30 | CF 30-2-AB | 90 | 35 | M30 × 1.5 | 32 | 37 | 100 | 63 | 15 | 1 | 4 | 8 | 1 | 46 |

| Stud diameter d | Part number | Basic Rated Load | Maximum Allowable Load F0 kN | Track Load Capacity | Limit rotation speed * | Weight | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| With cage | Full rollers | Cylindrical Outer Ring kN | Spherical Outer Ring kN | With cage min^-1 | Full rollers min^-1 | With cage g | Full rollers g | |||||

| C kN | C0 kN | C kN | C0 kN | |||||||||

| 12 | CF 12-AB | 7.87 | 9.79 | 13.4 | 19.8 | 9.37 | 7.06 | 2.45 | 14,000 | 5,800 | 105 | 107 |

| 12 | CF 12-1-AB | 7.87 | 9.79 | 13.4 | 19.8 | 9.37 | 7.45 | 2.74 | 14,000 | 5,800 | 115 | 117 |

| 16 | CF 16-AB | 12 | 18.3 | 20.6 | 37.6 | 17.3 | 11.2 | 3.14 | 10,000 | 4,500 | 205 | 207 |

| 18 | CF 18-AB | 14.7 | 25.2 | 25.2 | 51.3 | 26.1 | 14.4 | 3.72 | 8,500 | 3,800 | 295 | 300 |

| 20 | CF 20-AB | 20.7 | 34.8 | 33.2 | 64.8 | 32.1 | 23.2 | 8.23 | 7,000 | 3,400 | 525 | 530 |

| 20 | CF 20-1-AB | 20.7 | 34.8 | 33.2 | 64.8 | 32.1 | 21 | 7.15 | 7,000 | 3,400 | 450 | 455 |

| 24 | CF 24-AB | 30.6 | 53.2 | 46.7 | 92.9 | 49.5 | 34.2 | 10.5 | 6,500 | 2,900 | 915 | 925 |

| 24 | CF 24-1-AB | 30.6 | 53.2 | 46.7 | 92.9 | 49.5 | 39.8 | 12.9 | 6,500 | 2,900 | 1,150 | 1,160 |

| 30 | CF 30-AB | 45.4 | 87.6 | 67.6 | 145 | 73.7 | 52.6 | 14.9 | 5,000 | 2,300 | 1,880 | 1,890 |

| 30 | CF 30-1-AB | 45.4 | 87.6 | 67.6 | 145 | 73.7 | 56 | 16.1 | 5,000 | 2,300 | 1,950 | 1,960 |

| 30 | CF 30-2-AB | 45.4 | 87.6 | 67.6 | 145 | 73.7 | 59.3 | 17.3 | 5,000 | 2,300 | 2,000 | 2,010 |

*) Please refer to the digital catalog for accuracy standards.

* Compatible with unsealed, grease lubrication. Up to 130% of this value is acceptable for oil lubrication and up to 70% of this value for sealed.

Product features details

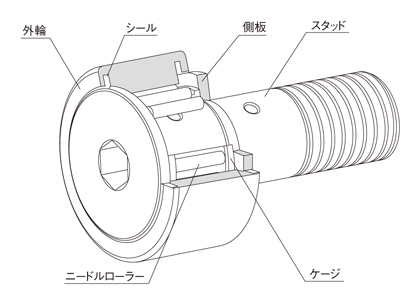

Figure 1 Cam Follower CF: UU-A type structure

Structure and features

A cam follower is a compact and highly rigid shaft bearing that has a needle roller built into it and is used as a cam mechanism and a guide roller for linear motion.

Since the outer ring rotates while in direct contact with the mating surface, it is designed to be thick and able to withstand impact loads.

In addition, a needle roller with a precision cage is built into the outer ring to prevent skewing, provide excellent rotation performance, and withstand high-speed rotation.

The outer diameter of the outer ring has a spherical surface and a cylinder, and the spherical outer ring easily absorbs the deviation of the axial center at the time of mounting and helps to alleviate the eccentric load.

It is widely used in automatic machines, cam mechanisms for dedicated machines, various conveyors, conveyors, bookbinding machines, tool changers for machining centers, pallet changers, automatic painting machines, sliding forks in automated warehouses, etc.

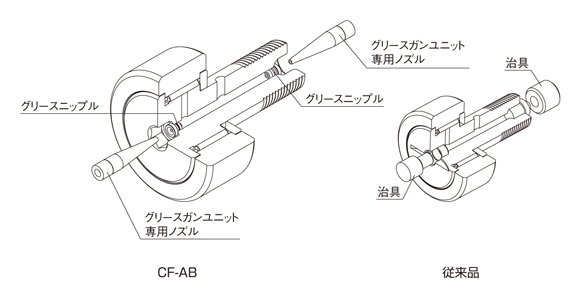

Cam follower with grease fitting

In the conventional product, it was necessary to manufacture a jig and attach a plug and grease nipple, but the cam follower CF-AB type with grease fitting has grease nipples on both sides, so it can be used immediately after taking it out of the box.

You can also use a hex key to fix the stud from either the head side or the threaded side, and you can lubricate from both directions. Work efficiency is improved because installation and maintenance can be performed without worrying about the installation space.

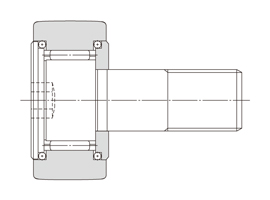

Cam follower with thrust ball

In a harsh high-speed cam mechanism, a slight mounting error may cause abnormal wear on the thrust of the cam follower, etc. In such a case, using the cam follower CFN type with thrust ball has a great effect on durability.

The CFN type can receive only the thrust load due to a slight mounting error, but please be careful in designing and assembling so that the thrust component force is not generated as much as possible.

Figure 2

Selection support information

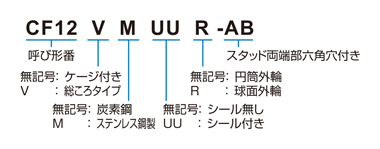

Part number configuration example

*) Please refer to the digital catalog for accessories.

Cautions/Prohibitions

Handling

(1) Do not disassemble each part. It may cause loss of function.

(2) Do not drop or hit the cam follower. It may cause injury or damage. Also, if it is impacted, it may lose its function even if it does not look damaged.

(3) When handling the product, wear protective gloves, safety shoes, etc., as necessary to ensure safety.

Usage precautions

(1) Refer to Digital Catalog Table 1 for the fastening torque when fixing the cam follower, and use a torque wrench or the like to turn the nut to fasten.

(2) Avoid using the product above 80°C. If this temperature is exceeded, the resin and rubber parts may be deformed or damaged.

(3) Be careful not to let foreign objects such as chips and coolant flow in. Excessive tightening will cause damage.

(4) If foreign objects such as chips adheres, clean it and then refill the lubricant.

(5) Since the cam follower supports radial load, avoid using it to apply thrust load.

(6) In the case of slight rocking, it is difficult for an oil film to form on the contact surface between the rolling surface and the rolling element, which may cause fretting, therefore, use grease with excellent fretting resistance. In addition, it is recommended to form an oil film on the rolling surface and rolling element by periodically applying an operation of about 1 rotation.

(7) If the rigidity and accuracy of the mounting member are insufficient, the bearing load will be locally concentrated and the bearing performance will be significantly reduced. Therefore, carefully consider the rigidity and accuracy of the housing and base, and the strength of the fixing bolts.

Lubrication

(1) Lithium soap-based grease No. 2 is used as standard grease for cam followers.

(CFN type uses urea grease No. 2)

Please re-grease as appropriate during use. Avoid relubricating different lubricants. Even if the greases have the same type of thickener, they may adversely affect each other due to different additives, etc. (See Digital Catalog Dust Protection and Lubrication)

(2) Apply lubricant between the cam follower and the rolling surface of the other party before use.

(3) CF, CFH24 and above cam followers (Symbol-A, excluding SUS) with hex socket heads have a structure that prevents grease from leaking from the hex sockets by press-fitting a plug into the through hole that connects the hex socket bottom and the grease hole (refer to ød1, ød2: Digital Catalog Dimensional Diagram).

When greasing, be careful not to remove the plug from the bottom of the hexagonal hole due to excessive pressure.

(4) When using the product in a place where vibration is constantly applied, in a cleanroom, in a vacuum, or in a special environment such as low or high temperature, use grease suitable for the specifications and environment.

(5) The cone penetration of grease changes depending on the temperature. Please note that the sliding resistance of the cam follower also changes depending on the change in cone penetration.

(6) After lubrication, the sliding resistance of the cam follower may increase due to the stirring resistance of the grease. Be sure to run-in and let the grease spread sufficiently before operating the machine.

(7) Even if it has a seal, excess grease may scatter around at the beginning of use or immediately after re-greasing, so wipe it off if necessary.

(8) Grease deteriorates in properties over time and its lubrication performance deteriorates, so it is necessary to check and replenish the grease according to the frequency of use.

(9) The greasing interval varies depending on the usage conditions and operating environment. Please set the final greasing interval and amount on the actual machine.

Storage

Please keep the cam follower indoors in the manufacturer's packaging, avoiding high temperature, low temperature and high humidity.

For products that have been stored for a long period of time, the internal lubricant may have deteriorated over time, so re-lubricate the product before use.

Disposal

Please dispose of the product appropriately as industrial waste.

| Part Number |

|---|

| CF18VUU-AB |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Outer Diameter D (Ø) | Width C (mm) | Roller Type | Cam follower stud screw (mm) | Material | Rolling Guide Method | Basic Load Rating Dynamic Rating (kN) | Basic Load Rating Static Rating (kN) | Allowable Rotational Speed (rpm) | Sealing Structure | Track Load Capacity (kN) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SGD 53.52 | 1 Piece(s) | 4 Day(s) or more | 10 | 40 | 20 | Cylindrical Outer Ring | M18 | Carbon Steel | Total roller type | 25.2 | 51.3 | 3800 | With Seal | 14.4 |

Loading...

Basic Information

| Product Category | Cam Followers | Fastening Methods | With Head Screw Part Hexagonal Hole | Cam Followers Type | Standard |

|---|---|---|---|---|---|

| Size Standard | Metric System | Roller Lining | No | Axis | Presence |

Please check the type/dimensions/specifications of the part CF18VUU-AB in the Cam Follower CF-AB Model series.

Specification/Dimensions

-

type

- CF-AB

- CF-M-AB

- CF-MR-AB

- CF-R-AB

- CF-V-AB

- CF-VM-AB

- CF-VMR-AB

- CF-VR-AB

-

Outer Diameter D(Ø)

-

Width C(mm)

-

Roller Type

- Spherical Outer Ring

- Cylindrical Outer Ring

-

Cam follower stud screw(mm)

-

Material

- Carbon Steel

- Stainless Steel

-

Rolling Guide Method

- With Gage

- Total roller type

-

Allowable Rotational Speed(rpm)

-

Sealing Structure

- No Seal

- With Seal

-

Track Load Capacity(kN)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 4 Day(s) or Less

- 11 Day(s) or Less

- 21 Day(s) or Less

- 22 Day(s) or Less

- 33 Day(s) or Less

- 83 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Similar Part Numbers

| Part Number |

|---|

| CF12-1R-AB |

| CF12-1UU-AB |

| CF12-1UUR-AB |

| CF18VUUR-AB |

| CF20-1-AB |

| CF20-1MUU-AB |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | RoHS | Outer Diameter D (Ø) | Width C (mm) | Roller Type | Cam follower stud screw (mm) | Material | Rolling Guide Method | Basic Load Rating Dynamic Rating (kN) | Basic Load Rating Static Rating (kN) | Allowable Rotational Speed (rpm) | Sealing Structure | Track Load Capacity (kN) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

SGD 34.10 | 1 Piece(s) | 4 Day(s) or more | 10 | 32 | 14 | Spherical Outer Ring | M12 | Carbon Steel | With Gage | 7.87 | 9.79 | 14000 | No Seal | 2.74 | ||

SGD 36.88 | 1 Piece(s) | 4 Day(s) or more | 10 | 32 | 14 | Cylindrical Outer Ring | M12 | Carbon Steel | With Gage | 7.87 | 9.79 | 14000 | With Seal | 7.45 | ||

SGD 44.67 | 1 Piece(s) | 4 Day(s) or more | 10 | 32 | 14 | Spherical Outer Ring | M12 | Carbon Steel | With Gage | 7.87 | 9.79 | 14000 | With Seal | 2.74 | ||

SGD 63.70 | 1 Piece(s) | 4 Day(s) or more | 10 | 40 | 20 | Spherical Outer Ring | M18 | Carbon Steel | Total roller type | 25.2 | 51.3 | 3800 | With Seal | 3.72 | ||

SGD 49.52 | 1 Piece(s) | 4 Day(s) or more | 10 | 47 | 24 | Cylindrical Outer Ring | M20 | Carbon Steel | With Gage | 20.7 | 34.8 | 7000 | No Seal | 21 | ||

SGD 180.04 | 1 Piece(s) | 22 Day(s) or more | 10 | 47 | 24 | Cylindrical Outer Ring | M20 | Stainless Steel | With Gage | 20.7 | 34.8 | 7000 | With Seal | 21 |

Tech Support

- Factory Automation, Electronics, Tools, & MRO (Maintenance, Repair and Operations)

- Tel:(65) 6733 7211 / FAX:(65) 6733 0211

- 9:00am - 6:00pm (Monday - Friday)

- Technical Inquiry

How can we improve?

How can we improve?